English

- English

- 中文

New development and application of ultrasonic technology

Click:

Time:2022-08-18 16:40:57

October 13-14, 2019 national power ultrasound academic conference was held in Hangzhou, Zhejiang Province. Experts and scholars from scientific research institutions engaged in ultrasonic research and production all over the country. Elite representatives from enterprises and units gathered together to discuss, display and share ultrasonic theory, ultrasonic equipment and ultrasonic application. They focused the development of power ultrasonic and the future of the industry.

As a representative enterprise, the Supersonic focusing on the research, development and application innovation of ultrasonic technology will present at the conference with its own research and development of ultrasonic tool holder, ultrasonic motorized spindle series standard products and personalized customized products. Zhang zengying, SEO of Supersonic, attended the conference and gave a speech entitled "enabling intelligent manufacturing, new development and application of ultrasonic technology".

Committed to the research and development of ultrasound technology and its products and launch the industry leading ultrasonic products.

Supersonic committed to the research, development and production of ultrasonic technology and its products. It has more than 70 patents. It has filled in a number of technical gaps in intelligent ultrasonic processing, ultrasonic control machine learning, ultrasonic control wireless transmission, etc. We have launched leading products of ultrasonic motorized spindle, ultrasonic transmission module and ultrasonic tool holder.

Compared with the traditional spindle with the same speed, the machining efficiency is higher and the quality is better;

Ultrasonic transmission module from 360 ° full circle transmission, 180 ° semicircle transmission to 30 ° - 360 ° arbitrary radian transmission full coverage, suitable for all machine tool magazine;

More than 10 ultrasonic toolholders can provide efficient and high-quality ultrasonic toolholder solutions for all ordinary toolholders, especially for the precision machining of hard and brittle materials such as ceramics, sapphire, glass, silicon carbide, hard alloy, etc., which can solve the problems that are not easy to process and fragile in the traditional way. At present, it is the first time in the world to realize the mass application of ultrasonic knife handle in the precision machining of 3C shell parts. The technical leadership and quality of the products have been recognized by the international well-known mobile phone enterprises and certified by their suppliers.

Personalized solutions to meet diversified production needs and improve customer effectiveness

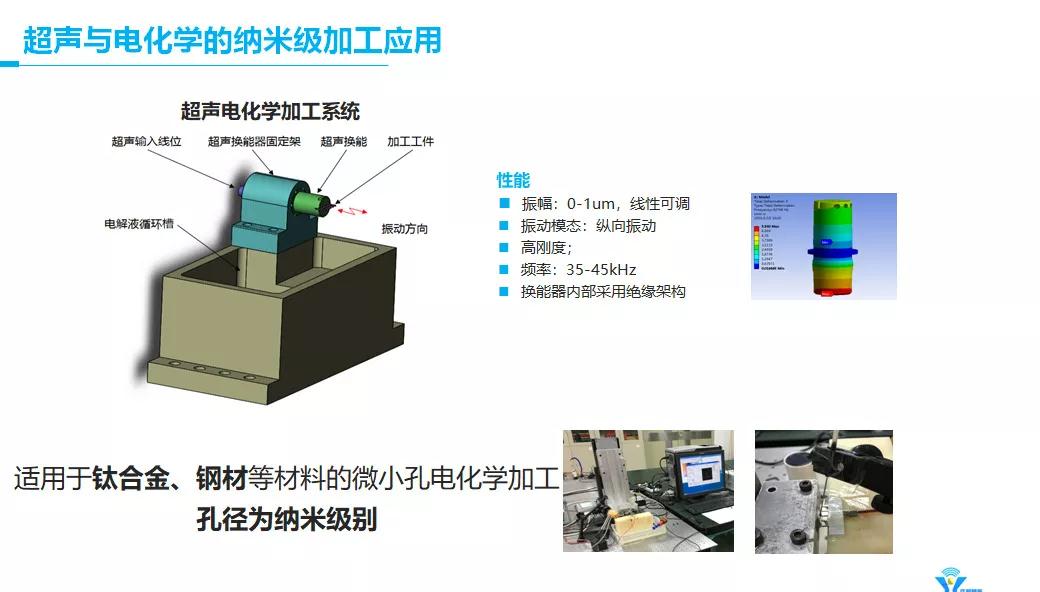

To provide customers with the right solutions, create lean production and improve customer efficiency are the enterprise values that Yuchao pursues. At the meeting, Yuchao shared the application of ultrasonic technology in bionics, lathe, chip processing in optical communication industry, micro hole electrochemical processing, aerospace titanium alloy plate workpiece forming, honeycomb material cutting, mobile phone shell processing, etc. Application examples:

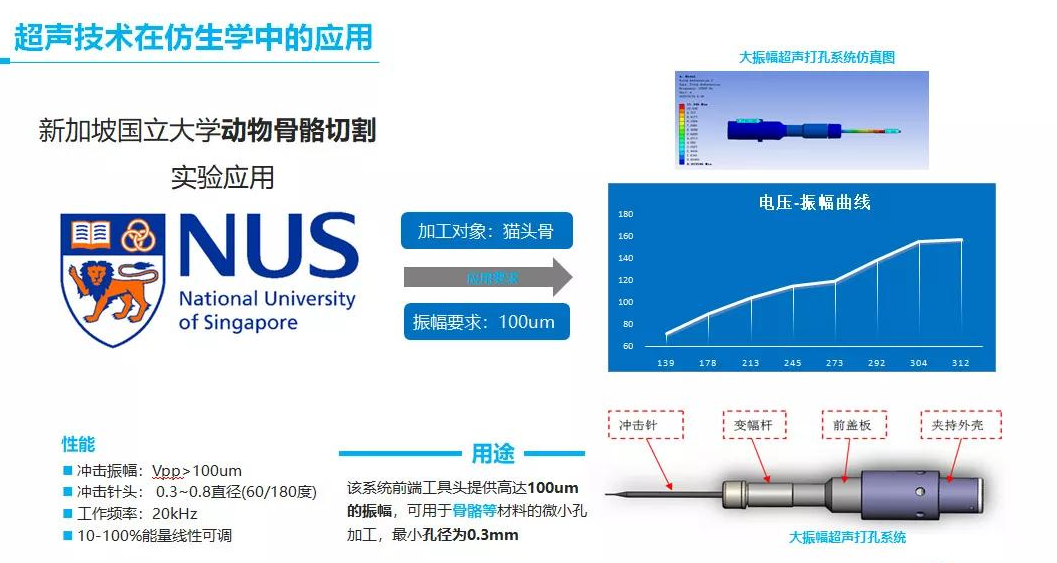

Application of ultrasonic technology in bionics

Application client: National University of Singapore

Amplitude requirement: 100um

Working objects: animal bones

Machining aperture: minimum aperture 0.3mm

Application of ultrasonic technology in machine tools

Applicable materials: aluminum, steel, carbon carbon composite new materials

Application effect: improve the surface finish of workpiece and prolong the tool life

Application of hand-held ultrasonic cutter

Applicable materials: carbon fiber, glass fiber, various honeycomb materials, etc

Cutting features: fast cutting speed & small resistance, no burr, no burning edge

The application of ultrasonic base & ultrasonic tool handle standard parts in the processing of mobile phone shell parts

Applicable process: milling, trenching, arc edge, fillet and other processing of ceramic back cover of mobile phone

Applicability: applicable to molds with different materials and processing shapes

Application customers: successfully applied to Huawei, apple and other mobile phone manufacturers

Application effect: the machining efficiency is increased by 15-40%, and the tool life is increased by 1.5-3 times

Application of hand-held ultrasonic cutter

Applicable materials: carbon fiber, glass fiber, various honeycomb materials, etc

Cutting features: fast cutting speed & small resistance, no burr, no burning edge

The application of ultrasonic base & ultrasonic tool handle standard parts in the processing of mobile phone shell parts

Applicable process: milling, trenching, arc edge, fillet and other processing of ceramic back cover of mobile phone

Applicability: applicable to molds with different materials and processing shapes

Application customers: successfully applied to Huawei, apple and other mobile phone manufacturers

Application effect: the machining efficiency is increased by 15-40%, and the tool life is increased by 1.5-3 times

News list

-

Great news. Zhang zengying, founder of Supersonic, is selected as the first batch of innovation and entrepreneurship leading talents in Songshan Lake.

-

Supersonic 10 * 7 ultrasonic sensor. Small but no limitation.

-

Want to build efficiency production, solve the problem of new material processing in 3C industry? Just choose Supersonic ultrasonic machining system!

-

Invitation. Supersonic invited all to Dongguan Machinery Exhibition for discussion and explore the new ultrasonic tech.

公安备案号 44190002004527

公安备案号 44190002004527